In every warehouse, a good shelving and racking solution is a must. Without a robust, efficient solution, your everyday operations will be chaotic, and you could even be putting members of staff at risk.

But what about the pieces of equipment which are often overlooked; the supporting accessories that are an integral cog in the machinery of your business? From security signage to extra shelves, every warehouse needs a range of extra pieces of equipment to ensure their business runs like clockwork. Take a look at these essential accessories that no warehouse environment can afford to be without.

Extra shelves

If you need to alter the configuration of your shelving at the last minute, to accommodate an awkwardly-shaped or cumbersome delivery, you’ll need to have some extra shelves handy. These come in the form of basic MDF sheets, or slotted timber decks, which provide sturdy support for your last-minute deliveries. Generally, two of the beams are required for each shelving level, and when it comes to the slotted timber options, there are sizes to suit both 900mm and 1100mm racking solutions. Stock up today so you’re not caught out.

Sack trucks

Perfect for transporting heavy loads around the warehouse without risking an injury, sack trucks should be in abundance around your workplace. Many of them come with pneumatic tyres, which means they’re ideal for moving heavier loads across rough terrain, which can often occur in loading bays or outdoor areas. There are various sack truck models available on the market, some of which can carry up to 200kg in weight. They require no specific training to use, and can be operated entirely by one person. Make sure there are plenty to hand in your warehouse.

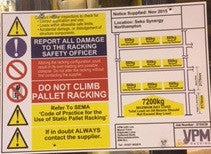

Security signage and load notices

You can never have too many notices about maximum loads in your warehouse – and the same goes for security signage. It’s important for staff to be able to see the maximum capacity of certain shelves at all times, so they don’t accidentally overload one of the racks and cause a potentially serious accident. One important tip: try to make sure all of your security signage and load notices are consistent. If you have different types of signage all over your warehouse, it can become confusing for staff – do ensure that your signage looks broadly similar, and that the maximum load weights are all in the same place on each sign.

Frame protectors

If you’ve just spend thousands of a new or used pallet racking system, the last thing you want is for it to be sustaining damage within the first few months of it being fully operational. Make sure you have plenty of frame protectors in place throughout your warehouse, so that if someone bumps a support with a pallet truck or a forklift, your shelving system won’t be damaged. This will help to protect your investment and ensure that any pallet racking systems you install will be there for the long-haul.

For more information about used pallet racking systems and accessories, browse the VPM Racking store today: http://vpm-racking.co.uk/collections/accessories